Drive Chain for Cinematic Camera Equipment

Introduction

Drive chains are an essential component of cinematic camera equipment, responsible for transferring power from the camera motor to the camera’s moving parts. Understanding the intricacies of drive chains is key to ensuring the smooth and reliable operation of high-end cinematic cameras.

The Basics of Drive Chains

Drive chains consist of a series of connected metal links that rotate around a toothed gear. The links in a drive chain are typically made of steel, while the teeth on the gear are made of hardened steel or other durable materials. The links are designed to fit snugly around the gear teeth, allowing for maximum power transfer with minimal slippage.

Types of Drive Chains

Roller Chains

Roller chains are the most commonly used type of drive chain in cinematic camera equipment. They consist of a series of steel links with cylindrical rollers that rotate around a toothed gear. Roller chains are known for their high tensile strength and durability, making them ideal for demanding camera applications.

Cotter Type Chains

Cotter type chains are a specialized type of drive chain that are used in specific camera applications. They consist of a series of steel links with cotter pins that secure the links in place. Cotter type chains are typically used in low-load applications where precision is critical.

Leaf Chains

Leaf chains are a type of drive chain that are characterized by their flat, leaf-shaped links. They are typically used in high-load applications where roller chains would be too weak to handle the load. Leaf chains are known for their exceptional strength and durability, making them an ideal choice for heavy-duty cinematic camera equipment.

Choosing the Right Drive Chain

Choosing the right drive chain for your cinematic camera equipment is essential to ensuring optimal performance and reliability. When selecting a drive chain, factors such as load capacity, operating conditions, and temperature range should be taken into consideration. It is also important to ensure that the drive chain is properly lubricated and maintained to prevent wear and tear.

Q&A

1. What is the load capacity of a typical roller chain?

A typical roller chain can handle a load capacity of up to 20,000 pounds.

2. What are some common causes of drive chain failure?

Common causes of drive chain failure include improper lubrication, excessive wear and tear, and overloading beyond the chain’s capacity.

3. Can cotter type chains be used in high-load applications?

No, cotter type chains are typically only used in low-load applications where precision is critical.

4. How often should drive chains be lubricated?

Drive chains should be lubricated at least once every 8 hours of operation.

5. What is the temperature range for a typical drive chain?

A typical drive chain can operate in temperatures ranging from -40 to 400 degrees Fahrenheit.

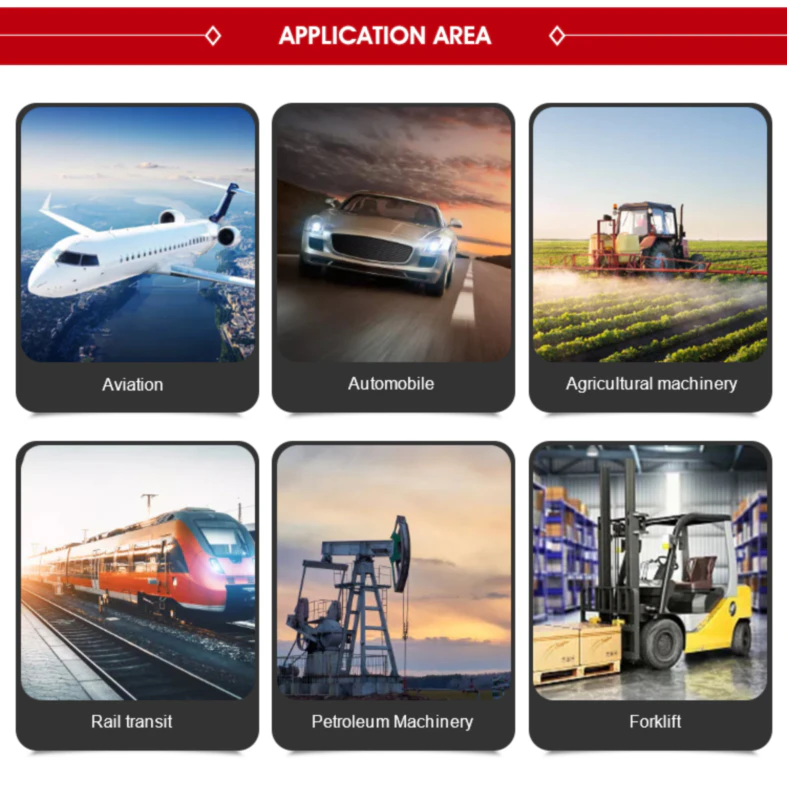

Company Promotion

Our company is a leading provider of drive chains in the Chinese market. We offer a wide range of products, including drive chains, bush chains, mill chains, leaf chains, conveyor chains, and cotter type chains. We use state-of-the-art automatic CNC production equipment and fully automated assembly equipment to ensure the highest quality products at competitive prices. We welcome custom orders and offer exceptional customer service and support. Visit our website at cottertypechain.top to learn more.