Drive Chain for Food Processing Equipment

Introduction

Drive chains are critical components in food processing equipment, ensuring the smooth and efficient operation of machinery. In this article, we will discuss the different types of drive chains used in the food industry, their functions, and the benefits of using high-quality drive chains.

Types of Drive Chains Used in Food Processing Equipment

Cotter Type Chain

The cotter type chain is a popular choice in food processing equipment due to its strength and durability. This chain is designed with cotters, which are pins that fit into holes in the links to hold them together. The cotter type chain is suitable for heavy-duty applications and can handle high loads.

Learn more about cotter type chain

Conveyor Chain

The conveyor chain is commonly used in food processing equipment to move products from one place to another. This chain is designed to withstand the stress of continuous use and can handle heavy loads. Conveyor chains come in a variety of sizes and configurations to suit different applications.

Bush Chain

The bush chain is known for its reliability and resistance to wear. This chain is designed with bushings that separate the inner and outer links, reducing friction and extending the life of the chain. Bush chains are commonly used in food processing equipment where high speeds and heavy loads are required.

Mill Chain

The mill chain is used in food processing equipment to move grain and other materials. This chain is designed with straight sidebars and cylindrical rollers that reduce friction and wear. Mill chains are suitable for high-speed applications and can handle heavy loads.

Leaf Chain

The leaf chain is designed with interlocking links that provide strength and flexibility. This chain is commonly used in food processing equipment where shock loads are expected. Leaf chains come in a variety of sizes and configurations to suit different applications.

Benefits of Using High-Quality Drive Chains

- Increased productivity

- Reduced downtime

- Improved safety

- Extended chain life

- Lower maintenance costs

Q&A

Q1: What is the maximum load that a cotter type chain can handle?

A1: The maximum load that a cotter type chain can handle depends on the size and configuration of the chain. Please consult the manufacturer’s specifications for more information.

Q2: Can conveyor chains be used in wet environments?

A2: Yes, conveyor chains can be designed to withstand wet environments. Stainless steel chains are a popular choice for wet environments as they are resistant to corrosion.

Q3: How often should drive chains be lubricated?

A3: The frequency of chain lubrication depends on the application and the type of chain used. Please consult the manufacturer’s recommendations for more information.

Q4: Can drive chains be repaired?

A4: Yes, drive chains can be repaired if they are not severely damaged. However, it is often more cost-effective to replace the chain rather than repair it.

Q5: What is the average lifespan of a drive chain?

A5: The lifespan of a drive chain depends on the application, the type of chain used, and the frequency of maintenance. Please consult the manufacturer’s recommendations for more information.

Company Promotion

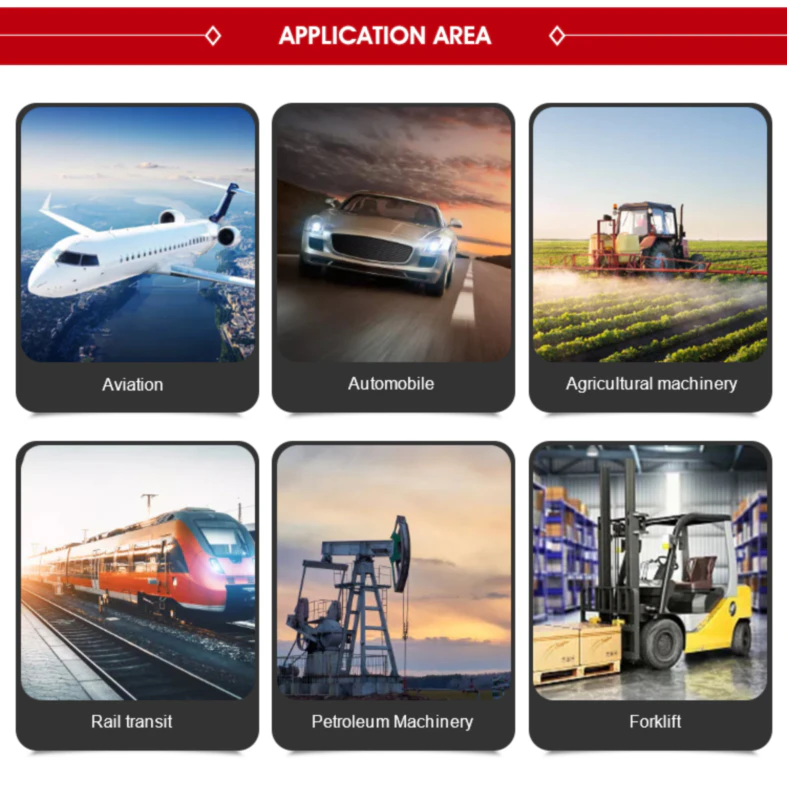

We are a leading company in the chain market in China, specializing in the production of drive chains, bush chains, mill chains, leaf chains, conveyor chains, cotter type chains, and more. Our products are made with high-quality materials and advanced production equipment to ensure their reliability and durability.

We offer competitive prices and excellent customer service, and welcome customers to contact us for custom orders or inquiries.