Drive Chain for Renewable Energy Systems

Renewable energy systems rely on many components to generate and transmit power. One critical component is the drive chain, which plays a key role in the system’s efficiency and reliability. In this article, we’ll explore the importance of drive chains in renewable energy systems and how they work.

What is a Drive Chain?

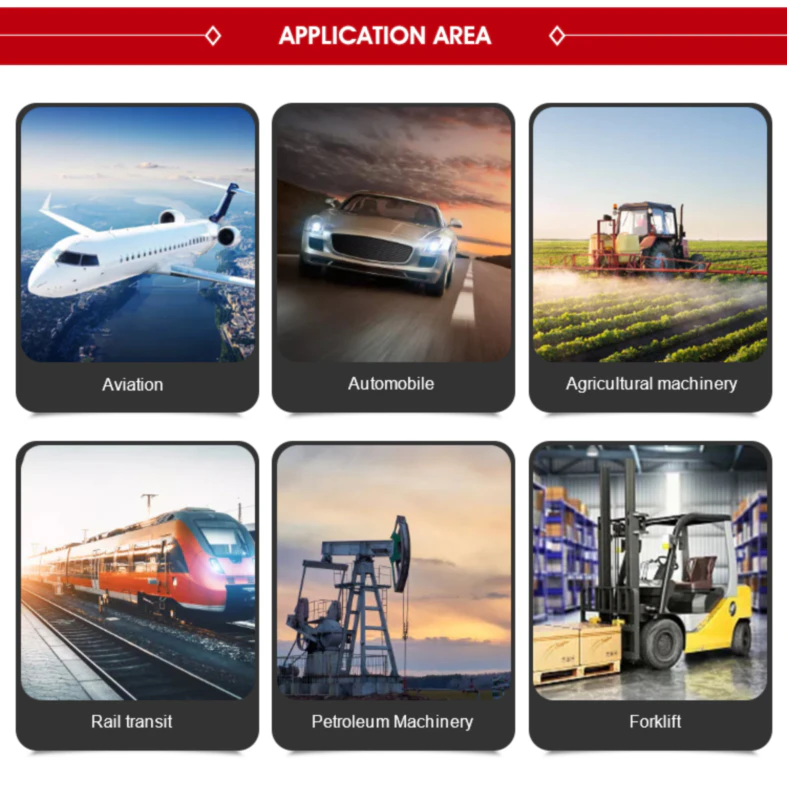

A drive chain is a mechanical component that transmits power from one part of a machine to another. It consists of a series of interconnected links that mesh with gears or sprockets to transfer rotational motion. Drive chains are commonly used in a variety of machinery, including automobiles, motorcycles, and industrial equipment.

How Does a Drive Chain Work?

The basic design of a drive chain consists of inner and outer plates, pins, and rollers. The inner and outer plates are connected by pins, which hold the rollers in place. The rollers, in turn, mesh with the teeth of gears or sprockets, allowing power to be transferred from one part of the machine to another.

Why Are Drive Chains Important in Renewable Energy Systems?

In renewable energy systems, drive chains are essential for transmitting power from the turbine to the generator. The drive chain must be able to withstand the harsh conditions of the environment and operate with high efficiency to ensure that the system generates as much power as possible. This is especially important in wind turbines, where the drive chain is exposed to constant vibration and shock loads.

What Are the Characteristics of a Good Drive Chain for Renewable Energy Systems?

A good drive chain for renewable energy systems should have several key characteristics. It should be able to withstand high loads, operate efficiently, and have a long service life. Additionally, it should be resistant to corrosion and wear, and be designed to minimize friction and noise.

What Types of Drive Chains Are Available for Renewable Energy Systems?

There are several types of drive chains that are suitable for renewable energy systems, including roller chains, silent chains, and cotter type chains. Roller chains are the most common type of drive chain and are well-suited for high-load applications. Silent chains, on the other hand, are designed to operate quietly and with minimal vibration. Cotter type chains are designed for heavy-duty applications and offer superior strength and durability.

If you’re looking for a high-quality cotter type chain for your renewable energy system, visit https://cottertypechain.top to learn more.

What Are the Benefits of Using Drive Chains in Renewable Energy Systems?

Using drive chains in renewable energy systems offers several benefits, including:

- Increased efficiency: Drive chains are designed to transmit power with high efficiency, which helps to maximize the amount of power generated by the system.

- Improved reliability: Drive chains are built to withstand harsh operating conditions and can be relied upon to operate consistently over a long period of time.

- Reduced maintenance: Because drive chains are designed to be durable and resist wear and tear, they require less maintenance than other types of power transmission components.

Q&A

Q1: What is the average service life of a drive chain in a renewable energy system?

A1: The average service life of a drive chain in a renewable energy system depends on several factors, including the type of chain, the operating conditions, and the maintenance schedule. In general, a high-quality drive chain that is properly maintained can last for many years.

Q2: Are drive chains difficult to install in a renewable energy system?

A2: Installing a drive chain in a renewable energy system requires some mechanical skill and knowledge, but it is not overly complicated. Following the manufacturer’s instructions and using the proper tools can help ensure a successful installation.

Q3: Can drive chains be repaired if they become damaged?

A3: In most cases, drive chains can be repaired if they become damaged. This may involve replacing individual links or rollers, or repairing the chain’s pins or plates. However, in some cases, it may be more cost-effective to replace the chain entirely.

Q4: How can I determine the correct size and type of drive chain for my renewable energy system?

A4: Determining the correct size and type of drive chain for your renewable energy system requires careful consideration of several factors, including the amount of power being transmitted, the operating conditions, and the environment. Consulting with a knowledgeable supplier of drive chains can help ensure that you select the right chain for your needs.

Q5: How can I ensure that my drive chain is properly maintained?

A5: Proper maintenance of your drive chain involves regular inspection, lubrication, and cleaning. Following the manufacturer’s recommended maintenance schedule and using high-quality lubricants can help ensure that your drive chain operates efficiently and has a long service life.

Company Promotion

Our company is a leading supplier of drive chains in the Chinese market. Our products include drive chains, bush chains, mill chains, leaf chains, conveyor chains, cotter type chains, and more. We have a variety of fully automated CNC production equipment and assembly equipment, allowing us to provide high-quality products at competitive prices. We welcome customers to contact us for custom orders or to learn more about our products.