Nickel-plated drive chain for aesthetic machinery

Introduction

The aesthetics of machinery have become increasingly important in recent years, with many manufacturers seeking to create products that not only perform well, but also look good. One of the key components in achieving this goal is the drive chain, which plays a critical role in the operation of many types of machinery. In this article, we will explore the benefits of using a nickel-plated drive chain in aesthetic machinery, and discuss the various applications in which it can be used.

Benefits of nickel-plated drive chain

Enhanced corrosion resistance

One of the main benefits of using a nickel-plated drive chain in aesthetic machinery is its enhanced resistance to corrosion. This is particularly important in applications where the machinery may be exposed to harsh environmental conditions, such as saltwater or chemicals. The nickel plating acts as a protective barrier, preventing the chain from corroding and extending its lifespan.

Improved aesthetics

In addition to its functional benefits, a nickel-plated drive chain can also improve the aesthetics of machinery. The shiny, metallic finish of the nickel plating gives the chain a sleek and professional look, making it an ideal choice for machinery that is designed to be on display.

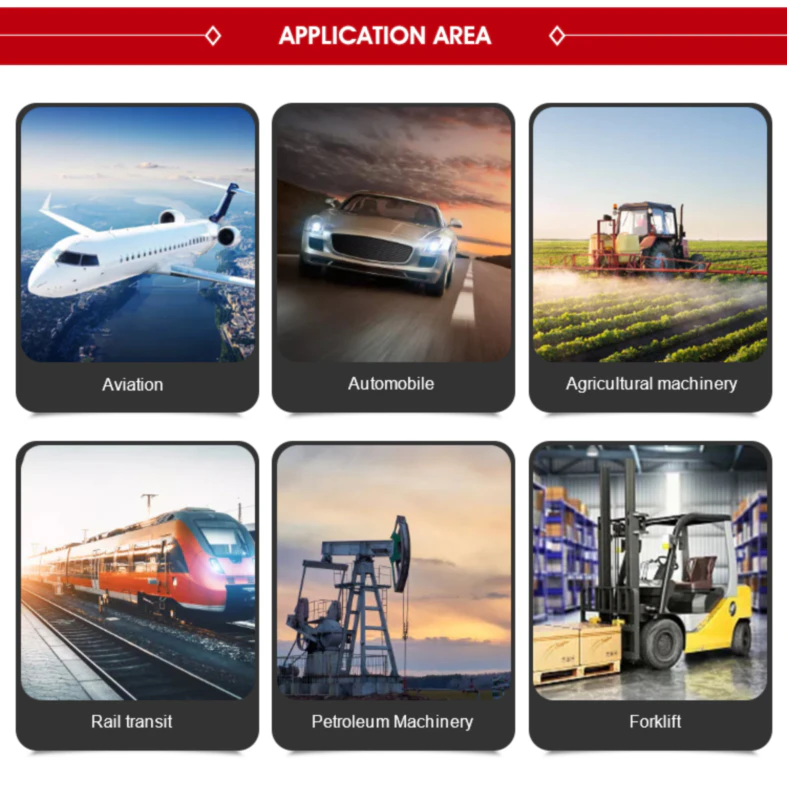

Applications

Automotive industry

The automotive industry is one of the primary applications for nickel-plated drive chains in aesthetic machinery. Many car manufacturers use nickel-plated chains in their engines and other components, as they provide both functional and aesthetic benefits. In addition to their corrosion resistance, nickel-plated chains are also resistant to wear and tear, making them a reliable choice for use in automotive applications.

Food and beverage industry

The food and beverage industry is another area where nickel-plated drive chains are commonly used. In this industry, machinery is often required to meet strict hygiene standards, and the use of nickel-plated chains can help to achieve this. The corrosion resistance of the nickel plating ensures that the chains remain free from rust and other contaminants, while the shiny finish makes them easy to clean and maintain.

Cotter type chain

Another type of chain that is commonly used in aesthetic machinery is the cotter type chain. This type of chain is characterized by its ability to be easily disassembled, making it ideal for applications where regular maintenance or replacement is required. To learn more about cotter type chain, please visit https://cottertypechain.top.

Company Promotion

Our company is a leader in the chain market in China, offering a wide range of high-quality products at competitive prices. Our products include drive chain, bush chain, mill chain, leaf chain, conveyor chain, cotter type chain, and more. We use state-of-the-art automated CNC production equipment and assembly equipment to ensure consistent quality and efficient production. We also offer customized products based on customer specifications. Please visit our website for more information.

Q&A

Q: What is the maximum load capacity of a nickel-plated drive chain?

A: The maximum load capacity of a nickel-plated drive chain depends on various factors, such as the size of the chain, the material it is made from, and the application it is used in. It is important to consult the manufacturer’s specifications to determine the maximum load capacity of a particular chain.

Q: Can nickel-plated drive chains be used in high-temperature applications?

A: Yes, nickel-plated drive chains are capable of withstanding high temperatures, but the maximum temperature will depend on the specific chain and its application. It is important to choose a chain that is designed for the specific temperature range of the application.

Q: How often should nickel-plated drive chains be lubricated?

A: The frequency of lubrication will depend on the specific chain and its application. In general, it is recommended to lubricate nickel-plated chains on a regular basis to ensure smooth operation and to prevent premature wear and tear.

Q: Can nickel-plated drive chains be repaired?

A: In some cases, it may be possible to repair a damaged nickel-plated drive chain by replacing individual links or sections. However, it is generally more cost-effective to replace the entire chain, especially if it is heavily worn or damaged.

Q: How does a nickel-plated drive chain compare to a stainless steel chain?

A: Both nickel-plated and stainless steel chains offer corrosion resistance and durability, but there are some differences between them. Nickel-plated chains are typically less expensive than stainless steel chains and offer a shiny, metallic finish. Stainless steel chains, on the other hand, offer greater resistance to corrosion and can be used in more extreme environments.