Sprocket and Drive Chain Compatibility

When it comes to choosing the right drive chain for your machinery, it’s important to consider compatibility with your sprockets. In this article, we’ll explore the factors that affect sprocket and drive chain compatibility and how to choose the right chain for your system.

Factors Affecting Compatibility

The following factors can affect sprocket and drive chain compatibility:

- Pitch: The pitch is the distance between pin centers on the chain. The pitch of the chain must match the pitch of the sprocket.

- Number of teeth: The number of teeth on the sprocket must match the number of chain links.

- Diameter: The diameter of the sprocket should be compatible with the chain’s minimum bend radius.

- Tooth profile: There are different tooth profiles for sprockets and chains. The profile of the sprocket teeth must be compatible with the profile of the chain links.

- Material: The material of the sprocket and chain must be compatible to ensure proper wear and longevity.

Choosing the Right Chain

When choosing the right chain for your system, consider the following factors:

- Load: Determine the maximum load your chain will be subjected to in order to choose the appropriate strength and size.

- Environment: Consider the temperature, humidity, and exposure to corrosive materials when selecting the appropriate chain material.

- Speed: Determine the maximum speed of your system to ensure the chain can handle the required RPM.

- Lubrication: Consider the frequency and method of lubrication to ensure proper wear and longevity of the chain.

Cotter Type Chain

The cotter type chain is a type of drive chain that uses cotter pins to connect the links. This type of chain is commonly used in applications with low to medium loads such as conveyor systems and agricultural machinery. Learn more about cotter type chains here.

Company Products

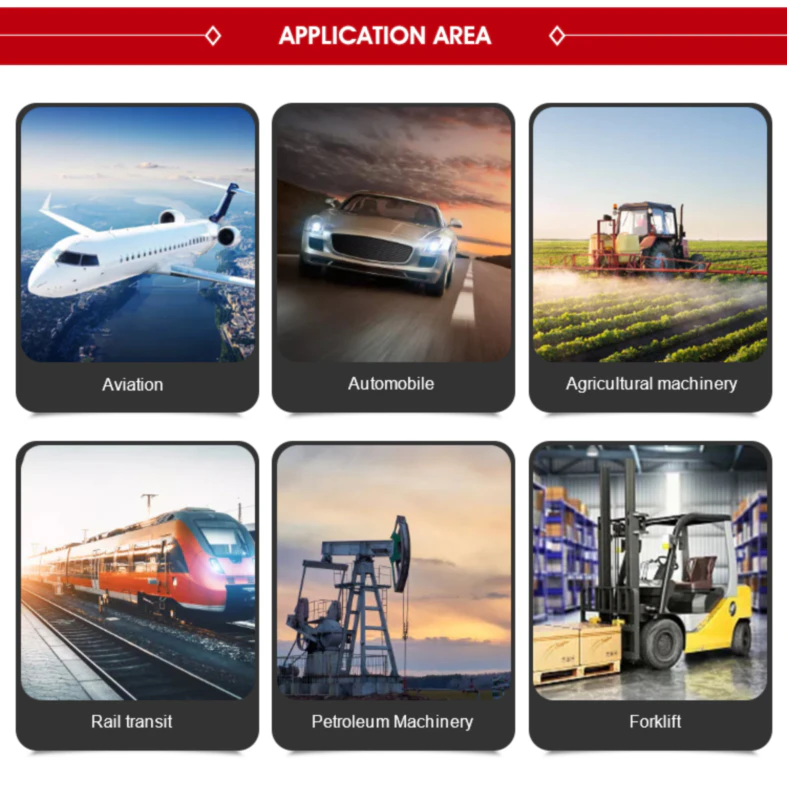

Our company is a leader in the China chain market, offering a wide range of products including drive chain, bush chain, mill chain, leaf chain, conveyor chain, and cotter type chain. With a variety of fully automated CNC production equipment and assembly equipment, we are committed to providing high-quality products at competitive prices with attentive customer service. We also offer custom solutions based on customer specifications.

Q&A

- Q: What lubricant should I use for my chain?

- Q: Can I use a chain with a larger pitch than my sprocket?

- Q: How often should I replace my chain?

- Q: Can I use a different type of chain on my existing sprockets?

- Q: Do you offer custom chain solutions?

A: The type of lubricant will depend on the environment and operating conditions of your system. Consult the manufacturer’s recommendations or speak to one of our experts for guidance.

A: No, the pitch of the chain must match the pitch of the sprocket for proper operation.

A: The lifespan of the chain will depend on the operating conditions and frequency of maintenance. Regular inspection and replacement as needed will extend the life of your system.

A: It is not recommended to mix different types of chains and sprockets as compatibility issues can arise, leading to premature wear and failure.

A: Yes, we offer custom solutions based on customer specifications. Contact us to discuss your needs.