Drive chain for industrial mixers and blenders

Introduction

Industrial mixers and blenders are essential components in a wide range of manufacturing processes. These machines are used for mixing, blending, and processing materials such as chemicals, pharmaceuticals, food products, and more. The drive chain is an important part of the mixer or blender that helps to transfer power from the motor to the mixing blades. In this article, we will take a closer look at drive chains for industrial mixers and blenders, including their design, construction, and maintenance.

Design and Construction

The drive chain for industrial mixers and blenders is typically made up of a series of interconnected links that are designed to transmit power from the motor to the mixing blades. These links are made from a variety of materials, including steel, stainless steel, and plastic. The design of the chain will depend on the specific application, including the size and power requirements of the machine.

Types of Drive Chains

There are several types of drive chains that are commonly used in industrial mixers and blenders, including:

- Roller chains

- Engineered plastic chains

- Leaf chains

- Cotter type chains

Roller Chains

Roller chains are one of the most common types of drive chains used in industrial mixers and blenders. These chains are made up of a series of interconnected rollers that are designed to mesh with the teeth of the sprocket on the motor and mixing blades. Roller chains are typically made from steel or stainless steel, and are known for their durability and reliability.

Engineered Plastic Chains

Engineered plastic chains are another type of drive chain that are commonly used in industrial mixers and blenders. These chains are made from high-strength plastic materials, such as polyethylene, which makes them lightweight and corrosion resistant. They are often used in applications where cleanliness is a top priority, such as in the food processing industry.

Leaf Chains

Leaf chains are a type of drive chain that are used in applications where high strength and shock resistance are required. These chains are made up of a series of interlocking plates that are connected by pins. They are often used in heavy-duty applications, such as in mining or construction equipment.

Cotter Type Chains

Cotter type chains are similar to leaf chains in that they are made up of a series of interlocking plates. However, these plates are connected by cotter pins, which makes them easier to disassemble and maintain. Cotter type chains are often used in applications where frequent maintenance is required, such as in conveyors or overhead cranes.

Maintenance

Proper maintenance is essential for ensuring the longevity and performance of the drive chain in an industrial mixer or blender. Regular maintenance tasks may include lubrication, cleaning, inspection, and replacement of worn or damaged parts. It is important to follow the manufacturer’s recommendations for maintenance, as well as to monitor the performance of the drive chain regularly to identify any potential issues before they become more serious problems.

Company Products

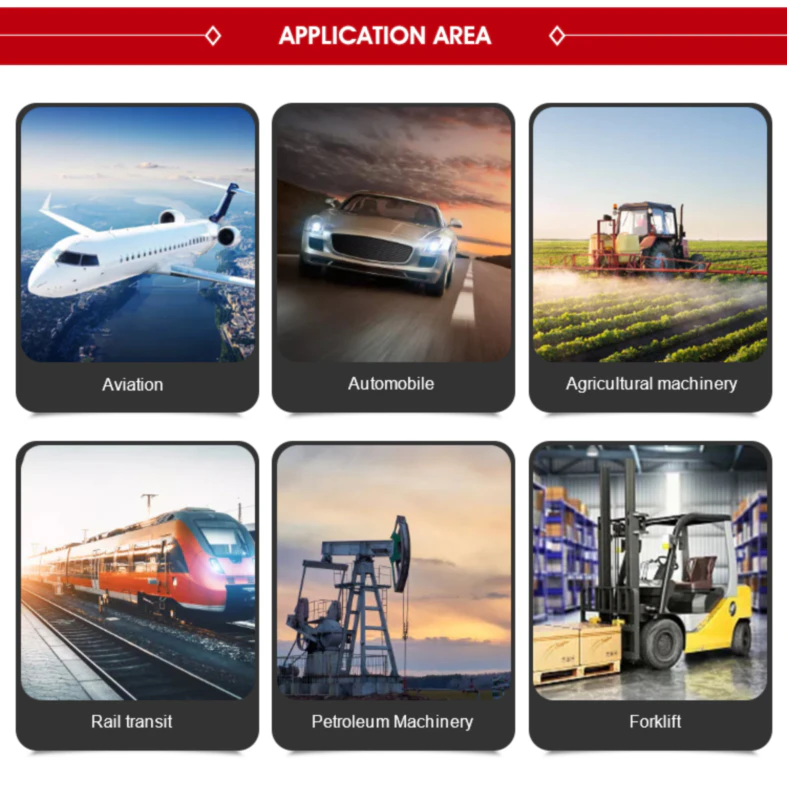

Our company is a leading provider of drive chains for the Chinese market. Our products include drive chains, bush chains, mill chains, leaf chains, conveyor chains, cotter type chains, and more. We have a wide range of fully automated CNC production equipment, as well as automatic assembly equipment to ensure the highest quality and consistency in our products.

Product Promotion

Our products are known for their high quality, competitive pricing, and exceptional customer service. We welcome customers to provide their own specifications and samples for customization. For more information on our products and services, please visit our website or contact us directly.

For more information on cotter type chains, please visit our website.

Q&A

Q: What is the maximum load capacity of your drive chains?

A: The maximum load capacity of our drive chains depends on the specific application and size of the machine. We offer a wide range of chain sizes and materials to meet the needs of our customers.

Q: How often should the drive chain be lubricated?

A: The frequency of lubrication will depend on the specific application and operating conditions of the machine. We recommend consulting the manufacturer’s recommendations for lubrication, as well as monitoring the performance of the chain regularly to identify any potential issues.

Q: Are your drive chains corrosion resistant?

A: Yes, many of our drive chains are made from materials that are corrosion resistant, such as stainless steel or plastic. We also offer additional coatings or treatments to enhance the corrosion resistance of our chains.

Q: Can your drive chains be customized?

A: Yes, we welcome customers to provide their own specifications and samples for customization. Our fully automated CNC production equipment and automatic assembly equipment ensure the highest quality and consistency in our customized products.

Q: Do you offer installation services for your drive chains?

A: We do not offer installation services, but we can provide technical support and guidance to ensure that our customers have the information they need to install our drive chains properly.