Drive Chain for Leather Processing Machines

When it comes to leather processing machines, the drive chain is an essential component that helps to keep the machines running smoothly. In this article, we will explore the different types of drive chains that are used for leather processing machines, their features, and the benefits they offer.

Types of Drive Chains

Roller Chain

The most common type of drive chain used in leather processing machines is the roller chain. It consists of a series of connected links with roller bearings in between. These bearings allow the chain to move smoothly over sprockets and other components, reducing friction and wear.

Engineering Chain

Engineering chain is a specialty chain that is designed for heavy-duty applications. It is commonly used in leather processing machines that require higher load capacity and greater durability. Engineering chains can be customized to meet specific requirements, such as resistance to high temperatures or corrosive environments.

Cotter Type Chain

Cotter type chain is a type of roller chain that is used in applications where the chain needs to be disassembled frequently. It features cotter pins that hold the links together, making it easy to remove and reassemble the chain.

Features of Drive Chains

Durable

Drive chains are designed to withstand the harsh operating conditions of leather processing machines. They are made from high-quality materials and are heat-treated for maximum strength and durability.

Low Maintenance

Drive chains require minimal maintenance, thanks to their self-lubricating properties. This helps to reduce downtime and increase productivity, as there is no need to stop the machines to lubricate the chains manually.

Efficient

Drive chains are designed to transfer power efficiently from the motor to the machine. This helps to reduce energy consumption and operating costs, while also improving the overall performance of the machines.

Benefits of Drive Chains

Increased Productivity

Drive chains help to keep the machines running smoothly, reducing downtime and increasing productivity. This is especially important in leather processing, where efficiency is key.

Reduced Maintenance Costs

Drive chains require minimal maintenance, which helps to reduce maintenance costs and increase the lifespan of the machines.

Improved Safety

Drive chains are designed to operate safely and reliably, reducing the risk of accidents or equipment failure. This helps to create a safer working environment for operators and other workers.

Q&A

Q: How often do drive chains need to be replaced?

A: The lifespan of a drive chain depends on several factors, including the type of chain, the application, and the operating conditions. In general, drive chains should be inspected regularly and replaced when they show signs of wear or damage.

Q: What is the difference between roller chain and engineering chain?

A: Roller chain is a general-purpose chain that is used in a wide range of applications. Engineering chain is a specialized chain that is designed for heavy-duty applications, such as those found in leather processing machines.

Q: Can drive chains be customized?

A: Yes, drive chains can be customized to meet specific requirements, such as resistance to high temperatures or corrosive environments.

Q: How do I know if my drive chain needs to be lubricated?

A: Most drive chains are self-lubricating, but it’s still important to inspect them regularly to ensure that they are properly lubricated. Signs that a chain needs to be lubricated include excessive noise, wear, or rust.

Q: What is the best way to clean and maintain drive chains?

A: Drive chains should be cleaned regularly to remove dirt, debris, and other contaminants. They should also be lubricated as needed to ensure smooth operation. Consult the manufacturer’s recommendations for specific cleaning and maintenance procedures.

About Our Company

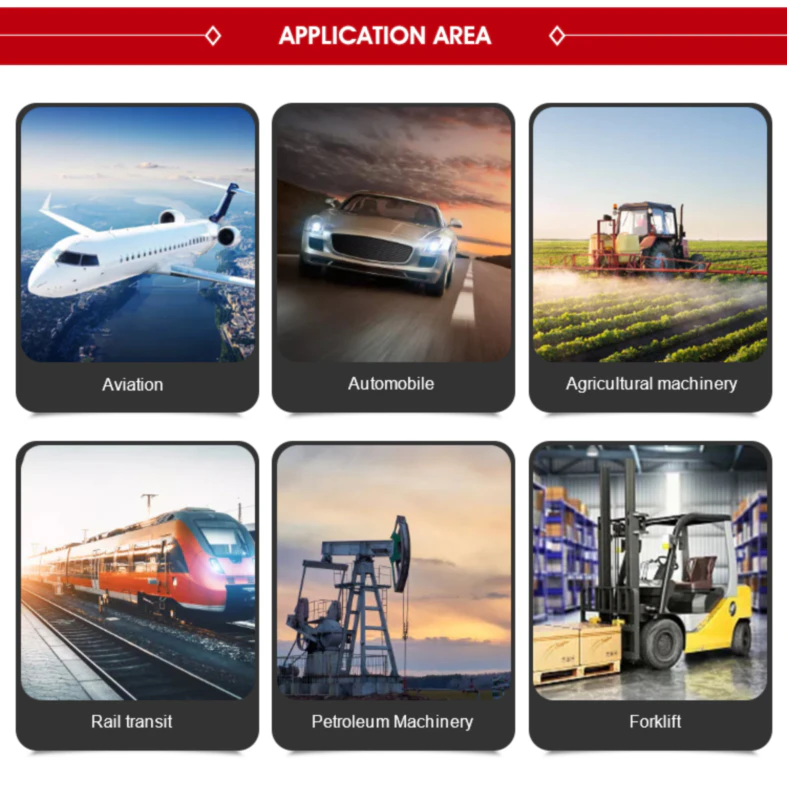

We are a leading company in the Chinese chain market, specializing in drive chains, bush chains, mill chains, leaf chains, conveyor chains, cotter type chains, and other chain products. We have a wide range of fully automatic CNC production equipment and automatic assembly equipment. We are committed to providing high-quality products, competitive prices, and excellent service to our customers. We welcome customers to contact us for custom orders and inquiries.