Specially Designed Drive Chain for Robotics Applications

The use of robotics in various industries has increased rapidly in recent years. As robots become more advanced and sophisticated, the need for high-quality components that can withstand the demands of robotic applications increases. One such component is the drive chain, which is a critical part of the robot’s powertrain.

What is a drive chain?

A drive chain is a mechanical component used to transmit power from one rotating shaft to another. It consists of a series of interconnected links that mesh with teeth on sprockets. As the sprockets rotate, the chain moves, transmitting power from one shaft to the other. Drive chains are commonly used in a variety of applications, including robotics.

Why is a specially designed drive chain necessary for robotics applications?

Robotics applications place unique demands on drive chains. Robots must be able to operate in harsh environments, such as extreme temperatures, high humidity, and exposure to corrosive chemicals. They must also be able to operate reliably for long periods without maintenance. Specially designed drive chains are necessary to meet these demands and ensure that the robot operates as intended.

What are the features of a specially designed drive chain for robotics applications?

Specially designed drive chains for robotics applications have several features that distinguish them from standard drive chains. First, they are made from high-quality materials that can withstand harsh environments. Second, they are designed to operate with minimal noise and vibration, which is critical for many robotics applications. Third, they have a high fatigue strength, which ensures a long service life. Finally, they are designed to operate with minimal maintenance, which reduces downtime and increases productivity.

What are the benefits of using a specially designed drive chain for robotics applications?

The benefits of using a specially designed drive chain for robotics applications are numerous. First, it ensures the reliable operation of the robot, which is critical for many applications. Second, it reduces downtime and maintenance costs, which increases productivity and reduces costs. Third, it improves the overall performance of the robot, which can lead to increased efficiency and throughput. Finally, it provides peace of mind, knowing that the robot is equipped with components that are designed to meet the demands of the application.

What is a cotter type chain?

A cotter type chain is a type of drive chain that uses cotter pins to connect the links. It is commonly used in agricultural equipment, such as hay balers, where it is exposed to harsh environments and heavy loads. The use of cotter pins makes it easy to disassemble and maintain the chain, which is important in these applications.

What are the advantages of using a cotter type chain?

The advantages of using a cotter type chain include easy assembly and disassembly, which reduces maintenance time and costs. It also provides increased flexibility, as the chain can be easily adjusted to fit different applications. Finally, the use of cotter pins makes it easy to replace damaged or worn links, which extends the service life of the chain and reduces costs.

Q&A

Q1: What is the load capacity of the specially designed drive chain for robotics applications?

A1: The load capacity of the specially designed drive chain for robotics applications varies depending on the specific application and requirements. However, it is designed to withstand heavy loads and operate reliably for long periods.

Q2: Can the specially designed drive chain be customized?

A2: Yes, the specially designed drive chain can be customized to meet the specific requirements of the application. Our company offers a range of customization options to ensure that the chain meets the demands of the application.

Q3: What is the service life of the specially designed drive chain?

A3: The service life of the specially designed drive chain varies depending on the specific application and operating conditions. However, it is designed to have a long service life and operate reliably for extended periods without maintenance.

Q4: What is the lead time for ordering a specially designed drive chain?

A4: The lead time for ordering a specially designed drive chain varies depending on the specific requirements of the application. However, our company has a fast and efficient production process to ensure that orders are fulfilled as quickly as possible.

Q5: What is the warranty period for the specially designed drive chain?

A5: The warranty period for the specially designed drive chain varies depending on the specific product and application. However, our company offers a comprehensive warranty to ensure that customers are satisfied with their purchase.

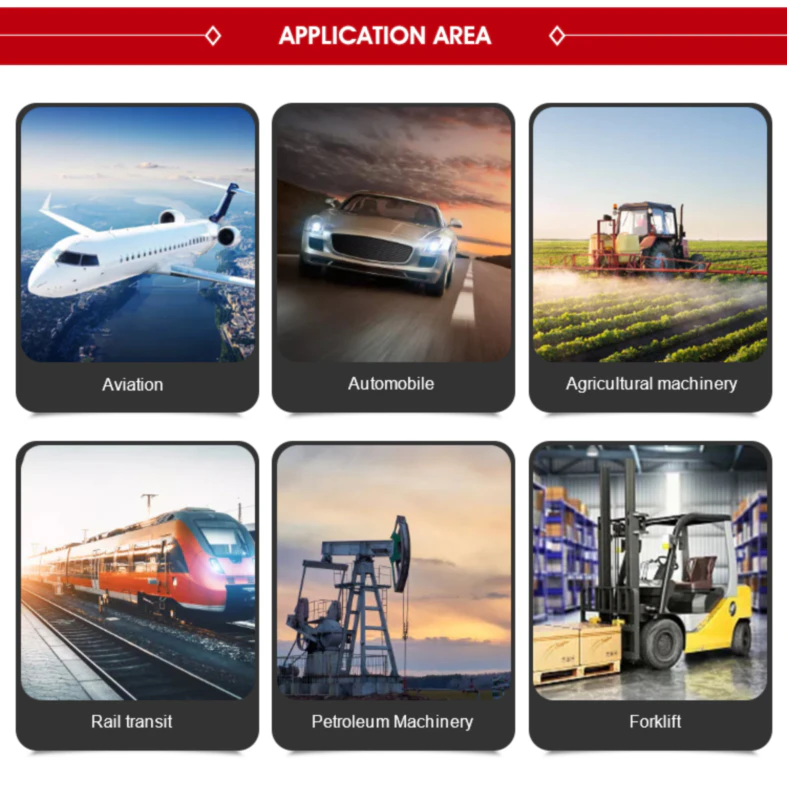

Our company is a leading provider of drive chain solutions in the Chinese market. We offer a wide range of products, including drive chain, bush chain, mill chain, leaf chain, conveyor chain, and cotter type chain. Our products are made from high-quality materials and are designed to withstand the demands of various applications. We have a range of fully automated CNC production equipment, as well as automated assembly equipment, to ensure that our products are of the highest quality. We pride ourselves on our competitive prices and excellent customer service. We welcome customers to contact us for custom orders and look forward to serving you.

For more information about our cotter type chain, please visit https://cottertypechain.top.