Drive Chain for Solar Panel Tracking Systems

Introduction

When it comes to solar panel tracking systems, one of the most important components is the drive chain. The drive chain is responsible for transmitting power from the motor to the solar panel tracker. It is essential that the drive chain is of high quality and durability in order to ensure the smooth and efficient operation of the tracking system.

How Drive Chains Work in Solar Panel Tracking Systems

Drive chains in solar panel tracking systems work by transmitting mechanical power from the motor to the solar panel tracker. The chain is made up of a series of interconnected links that mesh with the sprockets on the motor and tracker. As the motor turns, the chain rotates, which in turn rotates the tracker. This allows the solar panel to follow the sun’s movement throughout the day, optimizing its energy output.

Types of Drive Chains

Roller Chain

The most common type of drive chain used in solar panel tracking systems is the roller chain. Roller chains are composed of a series of cylindrical rollers that are held together by side links. These chains are highly durable and can handle heavy loads, making them ideal for solar panel tracking systems.

Bush Chain

Bush chains are similar to roller chains, but instead of rollers, they have bushings that are held in place by side plates. Bush chains are less common than roller chains in solar panel tracking systems, but they can be used in applications where the load is not as heavy.

Leaf Chain

Leaf chains are composed of interlocking links that resemble the leaves of a plant. These chains are highly flexible and are often used in applications where there is a need for a high degree of articulation.

Conveyor Chain

Conveyor chains are used in applications where there is a need to move materials from one place to another. These chains are composed of a series of interconnected links that are designed to fit around conveyor sprockets.

Cotter Type Chain

Cotter type chains are similar to roller chains, but they have added security features that prevent them from falling apart under heavy loads. These chains are commonly used in applications where safety is a concern, such as in elevators and escalators.

Advantages of Using Drive Chains in Solar Panel Tracking Systems

- High durability: Drive chains are designed to withstand heavy loads and provide long-lasting performance.

- Smooth operation: Drive chains are designed to provide smooth and efficient operation, which is essential for solar panel tracking systems.

- Low maintenance: Drive chains require minimal maintenance, which helps to keep operating costs low.

- Easy to install: Drive chains are easy to install, which means that solar panel tracking systems can be up and running quickly.

Q&A

Q: What is the maximum load that drive chains can handle?

A: The maximum load that drive chains can handle depends on the type of chain and the application. Roller chains are capable of handling the heaviest loads, while leaf chains are more flexible and are better suited for applications that require a high degree of articulation.

Q: How often do drive chains need to be replaced?

A: Drive chains are designed to provide long-lasting performance, but they will eventually wear out over time. The lifespan of a drive chain depends on a variety of factors, including the type of chain, the load it is carrying, and the operating conditions. In general, drive chains should be inspected regularly and replaced as needed to ensure optimal performance.

Q: Are drive chains difficult to install?

A: No, drive chains are relatively easy to install. However, it is important to follow the manufacturer’s instructions carefully to ensure that the chain is installed correctly and operates smoothly.

Q: Can drive chains be repaired?

A: Yes, drive chains can be repaired in some cases. However, it is often more cost-effective to replace the chain if it is damaged or worn out.

Q: What is the difference between roller chains and bush chains?

A: Roller chains and bush chains are similar, but they have some key differences. Roller chains are composed of cylindrical rollers that are held together by side links, while bush chains have bushings that are held in place by side plates. Roller chains are generally more durable and can handle heavier loads, while bush chains are better suited for lighter loads.

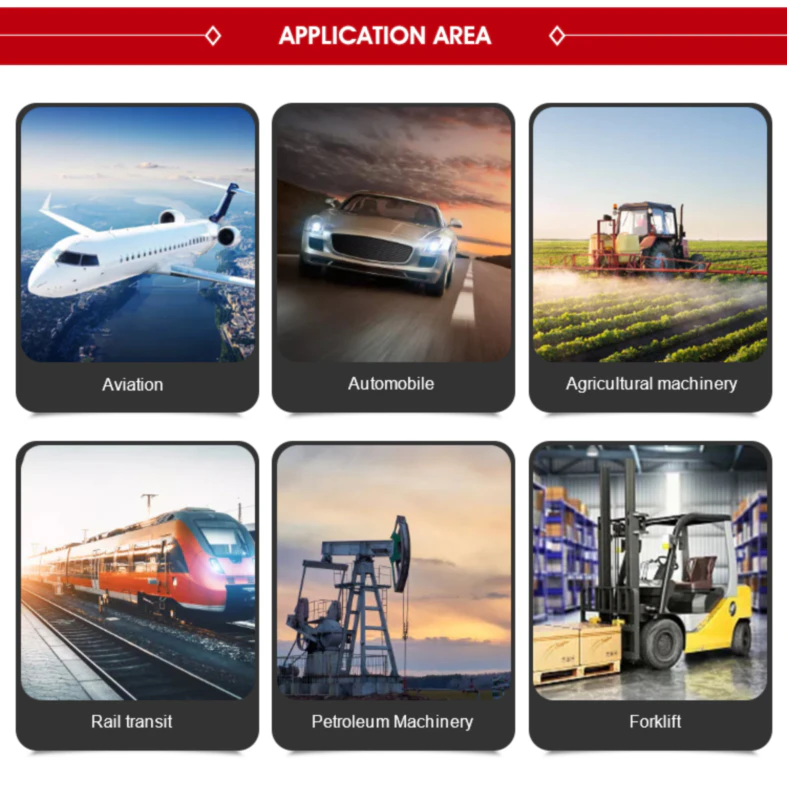

About Our Company

We are a leading supplier of high-quality chain products in China. Our product line includes drive chain, bush chain, mill chain, leaf chain, conveyor chain, cotter type chain, and more. We have a wide range of fully automatic CNC production equipment and automatic assembly equipment. Our company is committed to providing high-quality products, competitive prices, and excellent customer service. We welcome customers to contact us for custom orders or to request more information about our products.

If you are interested in learning more about our cotter type chain product, please visit https://cottertypechain.top.