Drive Chain for Robotic Arm Movements

Introduction

A drive chain is an essential component in the mechanism of a robotic arm. This chain helps in transferring mechanical power from the motors to the various joints of the robotic arm, enabling it to move and perform various functions.

Types of Drive Chain

Roller Chain

Roller chains are the most commonly used drive chains in robotic arms. They consist of rollers connected by links, and they run over sprockets, providing smooth and efficient power transfer.

Cotter Type Chain

Also known as the cottar link chain, this type of chain is characterized by its easy assembly and disassembly. It is widely used in robotic arms due to its durability and strength.

If you want to learn more about cotter type chain, click here.

Bush Chain

Bush chains consist of pins, bushings, and rollers. They are commonly used in robotic arms that require high-speed and low-noise motion.

Leaf Chain

Leaf chains are designed for high-stress applications and are ideal for use in robotic arms that require heavy lifting and high-torque motions.

Conveyor Chain

Conveyor chains are used to transport materials in robotic arms. They are commonly used in assembly lines and other manufacturing processes.

Benefits of Drive Chain

- High durability and strength

- Efficient power transfer

- Smooth operation

- Low noise production

- High-speed motion

FAQs

1. How do I choose the right drive chain for my robotic arm?

You should consider factors such as the weight of the arm, the speed of motion required, and the torque needed to perform various functions. Consulting with an expert can also help in selecting the right drive chain.

2. How often should I replace the drive chain?

You should replace the drive chain as soon as it shows signs of wear and tear. Regular maintenance and lubrication can also prolong its lifespan.

3. Can I use any type of chain in my robotic arm?

No, you should select the type of chain based on the requirements of your robotic arm.

4. How do I maintain the drive chain?

You should clean and lubricate the drive chain regularly to prevent wear and tear. You should also inspect it for signs of damage and replace it if necessary.

5. Can I customize my drive chain?

Yes, you can customize your drive chain by selecting the material, length, and type of chain required for your robotic arm.

Company Introduction

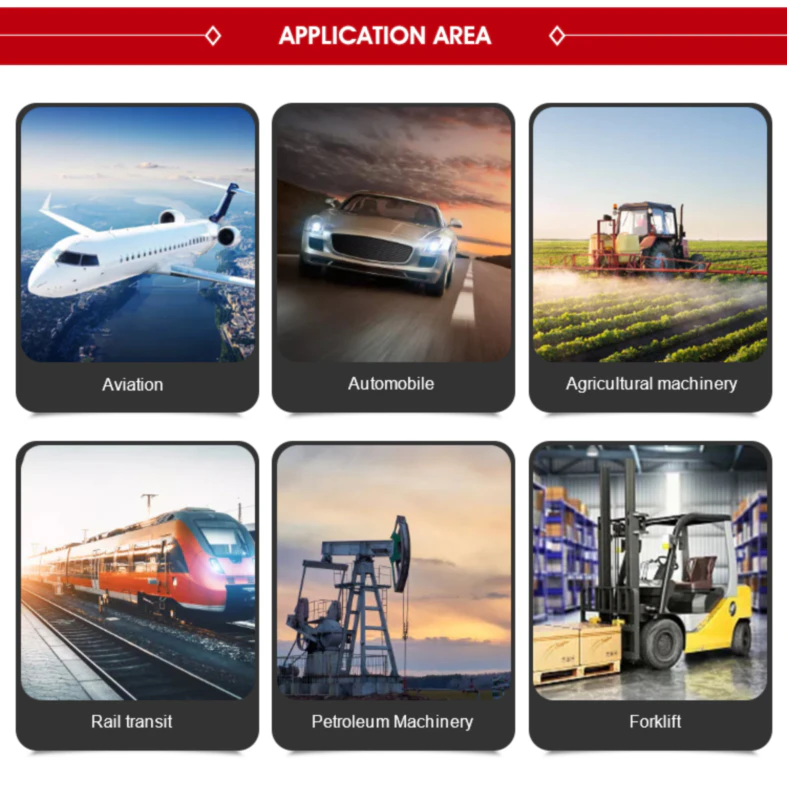

Our company is a leader in the chain market in China. We offer a wide range of products, including drive chains, bush chains, mill chains, leaf chains, conveyor chains, cotter type chains, and more. We have state-of-the-art CNC production equipment and automatic assembly equipment to ensure the quality and efficiency of our products.

If you are interested in our products or want to customize your chain, please contact us. We offer high-quality products at competitive prices and provide excellent customer service.